Unveiling the Secrets: How Sulfur Dioxide Production Costs Impact Industries

The latest report titled “Sulfur Dioxide Production” by Procurement Resource, a global procurement research and consulting firm, provides an in-depth cost analysis of the production process of sulfur dioxide.

Procurement Resource study is based on the latest prices and other economic data available. It also offers additional analysis of the report with detailed breakdown of all cost components (capital investment details, production cost details, economics for another plant location, dynamic cost model). In addition, the report incorporates the production process with detailed process and material flow, capital investment, operating costs along with financial expenses and depreciation charges.

Request Free Sample – https://www.procurementresource.com/production-cost-report-store/sulfur-dioxide/request-sample

Procurement Resource’s detailed report describes the stepwise consumption of material and utilities along with a detailed process flow diagram. Furthermore, the study assesses the latest developments within the industry that might influence Sulfur Dioxide production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Procurement Resource Assessment of Sulfur Dioxide Production Process:

1. From Sulfuric Acid through Thermal Decomposition: This report presents the detailed production methodology and cost analysis of Sulfur Dioxide industrial production across sulfur dioxide manufacturing plants. The production process initiates by subjecting concentrated sulfuric acid to high temperatures within a plug flow reactor. At this specific temperature range, the compound decomposes, yielding sulfur dioxide and water vapor. The resulting substances then undergo a heat recovery process in a boiler, leading to the emission of hot exhaust gases. These gases are promptly cooled down by being rapidly exposed to water, and the mixture subsequently undergoes purification to isolate and obtain pure sulfur dioxide as the end product

Request Free Sample – https://www.procurementresource.com/cost-analysis/sulfur-dioxide-production-using-sulfuric-acid-through-thermal-decomposition/requestsample

2. From Combustion of Molten Sulfur: This report provides the thorough economics of sulfur dioxide industrial production across sulfur dioxide manufacturing plants. Within this procedure, molten sulfur experiences combustion within a specialized burner under meticulously regulated air conditions. The resulting combustion gases are gathered and subsequently cooled. These gases are then introduced into a water-based system, passing through a series of towers where intricate dissolution processes occur, effectively removing moisture. Within the fourth tower, the resulting gas encounters a counterflow of sulfuric acid, facilitating drying. Finally, the end product is compressed into a liquid state to yield pure sulfur dioxide.

Request Free Sample – https://www.procurementresource.com/cost-analysis/sulfur-dioxide-production-by-the-combustion-of-molten-sulfur/requestsample

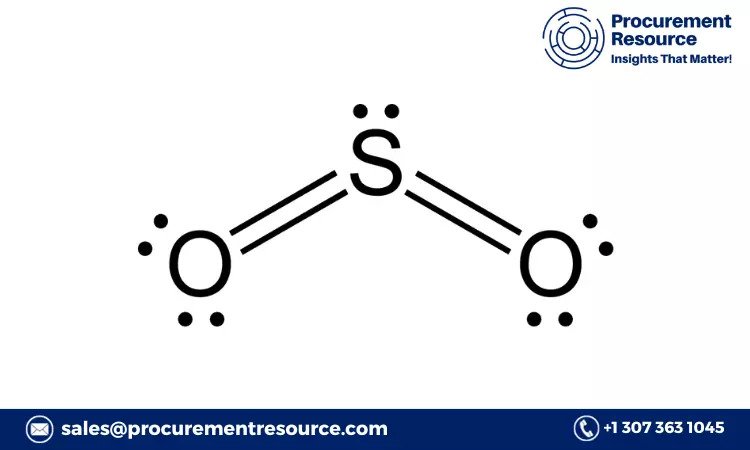

Product Definition:

Sulfur dioxide (SO2) is a colorless gas with a pungent odor. It is a chemical compound composed of one sulfur atom and two oxygen atoms. SO2 is primarily produced by the combustion of sulfur-containing materials like fossil fuels and is a significant air pollutant. It plays a crucial role in various industrial processes, including the production of sulfuric acid and as a preservative in the food industry. Additionally, it has applications in environmental monitoring, where it serves as an indicator of air quality and is involved in atmospheric chemistry, impacting climate and air pollution levels.

Market Drivers:

Sulfur dioxide (SO2) is a vital chemical with several market drivers. Firstly, it is a key component in the production of sulfuric acid, a fundamental industrial chemical used in various industries, including fertilizers, detergents, and batteries. Secondly, SO2 is employed in wastewater treatment and pollution control processes to remove harmful pollutants from industrial emissions. Thirdly, it serves as a preservative in the food and beverage industry, prolonging the shelf life of various products. Additionally, SO2 finds applications in the production of paper and textiles. These diverse uses, coupled with stringent environmental regulations, drive the demand for sulfur dioxide in today’s industrial landscape.

Looking for an exhaustive and personalised report that could significantly substantiate your business?

Although Procurement Resource leaves no page unfurled in terms of the rigorous research for the commodities that make the heftiest base of your business, we incline more towards tailoring the reports per your specificities. All you need is one-to-one consulting with our seasoned consultants to comprehend the prime parameters you are looking to pin your research on.

Some of the common requests we receive from our clients include:

- Adapting the report to the country/region where you intend to establish your plant.

- Adjusting the manufacturing capacity of the plant according to your needs.

- Customizing machinery suppliers and costs to meet your requirements.

- Providing additional information to the existing scope based on your needs.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertakes extensive research to provide our customers with the latest and up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele.

Procurement Resource work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. As a team of experts, we also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with updated and reliable data.

We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate so that they can form strategies that ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Byrd

Email: [email protected]

Toll Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500

Address: 30 North Gould Street, Sheridan, WY 82801, USA