Surface Inspection Market Projected to Garner Significant Revenues By 2032

Market Overview

According to MRFR analysis, The Surface Inspection industry is projected to grow from USD 4.22 Billion in 2023 to USD 7.25 Billion by 2030, exhibiting a compound annual growth rate (CAGR) of 8.21% during the forecast period (2023 – 2030). The word “surface inspection” describes the practice of looking at an object or material’s surface to assess its physical properties, including its size, shape, texture, and existence of any flaws or blemishes. To make sure that items satisfy certain standards and regulations, this can be carried out manually or with the use of automated inspection systems. It is frequently used in a variety of sectors, including manufacturing, quality control, and product inspection.

A key driver of the market’s expansion has been the rising demand for high-quality goods. Customers are expecting products with better standards of quality and dependability, which has caused numerous businesses to place more focus on inspection procedures.

This has sparked the creation of increasingly sophisticated surface inspection techniques and technologies that are intended to guarantee that items comply with criteria and standards while minimising flaws and faults. In turn, this has encouraged the market’s expansion.

Industry News

The system created by Ford Motor Company employs a moving framework made up of multiple elevated fluorescent tubes and wireless controllers surrounding the stationary vehicle body to identify millimetric faults of 0.3-millimeter diameter or more with diverse forms that are extremely difficult to detect, thereby enhancing manual inspection performance. There has been a rise in focusing on identifying in the car industry, which has increased demand for surface inspection.

REQUEST FREE SAMPLE REPORT – https://www.marketresearchfuture.com/sample_request/879

Key Players

Important participants include FLIR Systems, Keyence Corporation, Ametek, Sony Corporation, Teledyne Technologies Inc., Edmund Optics, Baumer Holding, and Industrial Vision Systems Ltd.

Introduction:

In today’s fast-paced and highly competitive industrial landscape, ensuring product quality is crucial for businesses to maintain a competitive edge and meet customer expectations. The advent of advanced technologies has opened up new avenues for quality assurance, and one such cutting-edge solution is surface inspection. This blog will delve into the growing significance of surface inspection in the industry and explore its potential to revolutionize quality control processes.

- The Basics of Surface Inspection:

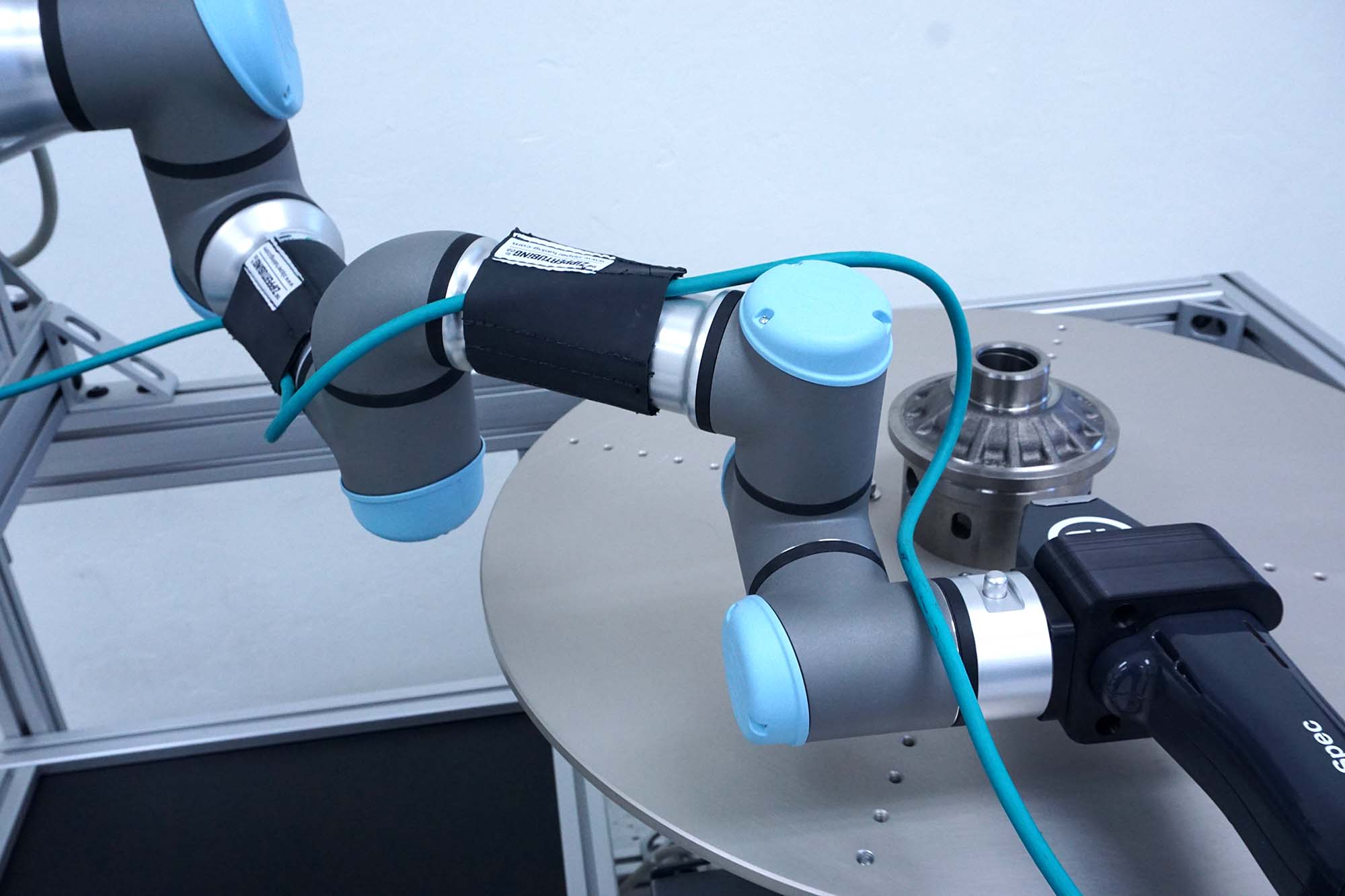

Surface inspection is a non-destructive testing technique that involves the automated examination of the surface of a product to detect defects, anomalies, or irregularities. By employing various imaging and analysis methods, surface inspection systems can identify flaws such as scratches, dents, cracks, color variations, and other imperfections that may impact product quality. These systems utilize advanced cameras, sensors, machine vision algorithms, and artificial intelligence to achieve high levels of accuracy and reliability in defect detection.

- Enhanced Quality Control:

With the increasing complexity and sophistication of modern manufacturing processes, traditional manual inspection methods have become inadequate in ensuring consistent and reliable product quality. Surface inspection technology offers a significant advantage by providing automated, objective, and repeatable inspection capabilities. By eliminating human error and subjectivity, businesses can achieve higher levels of accuracy and consistency in quality control, leading to enhanced customer satisfaction and reduced product recalls or rejections.

- Improved Efficiency and Cost Savings:

Surface inspection systems not only enhance quality control but also contribute to improved operational efficiency and cost savings. By automating the inspection process, businesses can achieve higher inspection speeds, leading to increased production throughput. Moreover, early defect detection enables timely intervention, reducing the need for costly rework or scrap. Surface inspection technology also facilitates proactive maintenance by identifying potential issues in production equipment, thus minimizing downtime and optimizing productivity.

- Wide Applications Across Industries:

The applications of surface inspection are vast and encompass various industries. In automotive manufacturing, surface inspection systems ensure the flawless finish of vehicle bodies, detect paint defects, and inspect critical components for flaws. In the electronics industry, these systems play a pivotal role in inspecting printed circuit boards (PCBs), identifying soldering defects, and validating component placement accuracy. Surface inspection is also extensively utilized in the pharmaceutical industry to detect contamination, verify label printing, and ensure the integrity of packaging.

- Advancements in Technology:

The rapid advancements in imaging technology, machine vision algorithms, and artificial intelligence have significantly propelled the capabilities of surface inspection systems. High-resolution cameras with sophisticated optics enable the detection of minuscule defects, while advanced algorithms leverage deep learning techniques to continually improve defect recognition and classification. The integration of AI-driven systems with robotic automation further enhances the efficiency and effectiveness of surface inspection processes.

Related Reports:

Vision Positioning System Market – https://www.marketresearchfuture.com/reports/vision-positioning-system-market-3204

HDR (High Dynamic Range) Video Camera Market – https://www.marketresearchfuture.com/reports/hdr-video-camera-market-3836

Conclusion:

In an era where quality control plays a pivotal role in brand reputation and customer loyalty, surface inspection technology offers a transformative solution. By leveraging advanced imaging, machine vision, and AI-driven algorithms, businesses can achieve unparalleled levels of accuracy, efficiency, and cost savings in their quality assurance processes. As the market for surface inspection continues to expand, it is imperative for organizations to embrace this technology to remain competitive and meet the evolving demands of customers and regulatory bodies. With its potential to revolutionize quality control, surface inspection is undoubtedly a game-changer in the industry.