Maximizing Diesel Engine Performance: The Role of Engine Surveillance Systems

Introduction

In the realm of industrial machinery, diesel engines reign supreme for their robustness and reliability. However, ensuring their optimal performance demands vigilance and precision. The emergence of engine surveillance systems has revolutionized the landscape, offering real-time insights into engine health and functionality. Among these systems, vibration monitoring software stands out as a pivotal tool, complemented by the integration of wireless condition monitoring. At Icon Research, we delve deep into this amalgamation of technology and precision engineering to redefine the standards of diesel engine analysis.

Understanding Diesel Engine Analysis

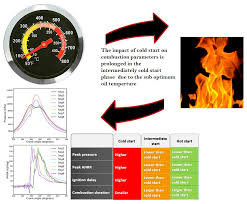

Diesel engines, hailed for their efficiency and power, operate under extreme conditions. Analyzing their performance involves meticulous scrutiny of various parameters. From fuel consumption and emissions to temperature and vibration patterns, every aspect plays a role in determining the engine’s health.

Engine surveillance system equipped with advanced sensors and data analytics provide a comprehensive overview. These systems not only monitor but also predict potential issues, enabling preemptive maintenance and minimizing downtime.

The Power of Engine Surveillance System

Icon Research’s commitment to enhancing diesel engine performance revolves around cutting-edge surveillance systems. Our integration of vibration monitoring software facilitates the detection of minute irregularities within the engine’s mechanisms. This software interprets vibrations as indicators, revealing anomalies that might otherwise go unnoticed.

Wireless condition monitoring further amplifies this prowess by enabling remote access to real-time data. This allows for proactive decision-making, swift response to fluctuations, and the execution of preventive measures, thereby optimizing the engine’s functionality and longevity.

Advantages of Vibration Monitoring Software

Vibration monitoring software serves as the cornerstone of comprehensive engine surveillance. By analyzing vibration patterns, it detects deviations that could signify impending issues. These deviations might range from misalignments to wear and tear in crucial components.

Moreover, the software’s ability to differentiate between normal and abnormal vibrations ensures accurate diagnostics. This precision aids in identifying specific areas needing attention, streamlining maintenance efforts, and ultimately reducing operational costs.

Wireless Condition Monitoring: Revolutionizing Engine Maintenance

The adoption of wireless condition monitoring marks a paradigm shift in engine maintenance practices. This technology facilitates real-time data transmission, enabling instantaneous analysis irrespective of geographical constraints. Such immediacy empowers engineers to make informed decisions promptly, significantly reducing response times to critical issues.

Furthermore, the wireless aspect eliminates the need for physical connections, ensuring minimal disruption to ongoing operations while maintaining a continuous flow of data.

Conclusion

In the pursuit of optimal diesel engine performance, the integration of engine surveillance systems, particularly leveraging vibration monitoring software and wireless condition monitoring, stands as a game-changer. Icon Research spearheads this revolution by prioritizing precision, real-time insights, and proactive maintenance strategies.

Engineered to perfection, these systems not only ensure enhanced performance but also fortify the reliability and longevity of diesel engines, paving the way for unparalleled efficiency in industrial operations.